Climate Change Initiatives

Plastic Use Reduction

In September 2022, the packaging for "freeze-dried powder-type instant miso soup" was changed from plastic (bag form) to paper (box form). This reduces the use of plastic by 12 tons per year.

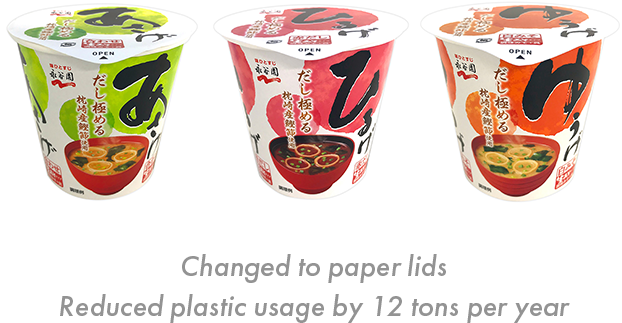

The lid of the "miso soup in a cup" was changed from plastic to paper as well. This also reduces the use of plastic by 12 tons per year.

The lid of the "miso soup in a cup" was changed from plastic to paper as well. This also reduces the use of plastic by 12 tons per year.

Usage of Biomass Raw Materials

Since 2017, we have been using a packaging material made of biomass plastic for the outer bag of our large-size pack of 10-servings of miso soup. Biomass plastic is an environmentally friendly packaging material that reduces the use of petroleum, a depletable resource, by using plant-derived raw materials for some of its components, thereby reducing CO2 emissions compared to conventional petrochemical-derived plastics.

Since April 2021, we have been using biomass ink, which uses plant-derived resources as part of its raw materials, for the packaging of our major products such as prepared food ingredients and furikake (seasoning sprinkles for rice dishes).

Since April 2021, we have been using biomass ink, which uses plant-derived resources as part of its raw materials, for the packaging of our major products such as prepared food ingredients and furikake (seasoning sprinkles for rice dishes).

Energy Conservation

The Nagatanien Group is working to promote the use of renewable energy sources such as solar power in order to realize a zero carbon society. Solar panels have been installed on the roofs of the Nagatanien Foods Co., Ltd.(Nagatanien Foods) Sunflex plants No. 1 and No. 2 factories. By prioritizing the use of solar-generated electricity and complementing that with diesel generators, we continue to have a stable flow of electricity while reducing total use. In 2021, we generated 223,337 kWh of solar power and reduced CO2 emissions by 106 tons.

Since January 2022, the Ibaraki plant of Nagatanien Foods has switched to electricity from virtually renewable sources with tracking and FIT non-fossil certificates. This is expected to reduce CO2 emissions by approximately 1,220 tons a year.

Since January 2022, the Ibaraki plant of Nagatanien Foods has switched to electricity from virtually renewable sources with tracking and FIT non-fossil certificates. This is expected to reduce CO2 emissions by approximately 1,220 tons a year.

Introduction of Renewable Energy

The Chaucer group has acquired ISO 50001 certification and is working to visualize and improve the organization's energy performance.

It works to reduce energy consumption by saving electricity by better startup/shutdown management of manufacturing equipment and adopting environmentally friendly fuels for its bread business baking machines.

It works to reduce energy consumption by saving electricity by better startup/shutdown management of manufacturing equipment and adopting environmentally friendly fuels for its bread business baking machines.

Plastic Replacement

Muginoho (now DAY TO LIFE)'s Beard Papa's stores have swapped plastic shopping bags for bags containing 25% biomass material. In some stores, plastic straws have been replaced with paper straws.

Initiatives at JSL Foods

Recycling Efforts

JSL Foods' Pasadena and Indiana plants design their production lines so no oil is released into the wastewater, and the extracted oil waste is handed over to a recycling company. By removing oil content from factory wastewater in advance, we reduce both the oil that is discharged into the sewage system and the cost of wastewater treatment. We also actively recycle cardboard.